Berger as a service provider

A strong partner in all areas

An overview of our services:

Process development

The process development phase defines how the product should be manufactured. It is imperative that the correct manufacturing process is determined, which is why the process development phase is of utmost importance. As a result, we are able to offer our customers significant potential savings through optimization of machining sequences, and the choice of machine concepts.

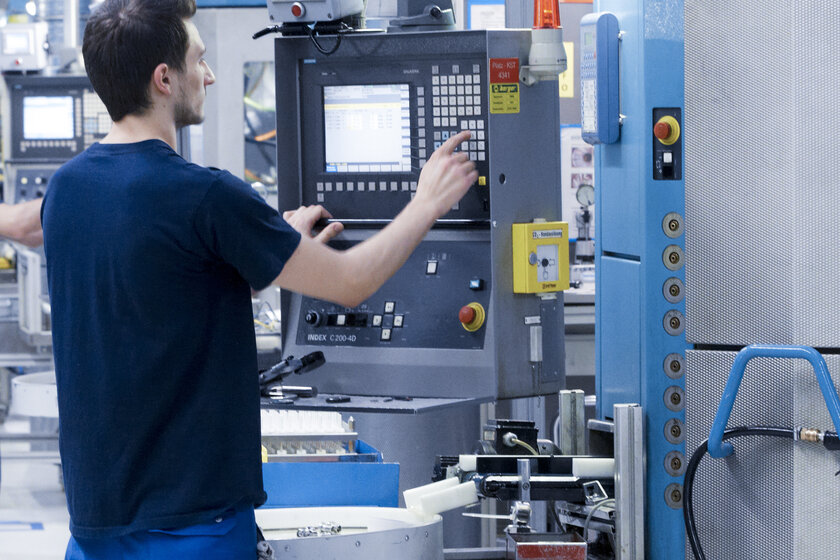

Machine development

To meet the needs of our customer requirements, we have developed modern machining centers, automated testing machining that result in production systems that are able to further increase the efficiency of production.

For especially demanding projects, Berger has the use of the Bergomat CTC 16. This machine, developed at Berger, enables us to produce efficiently and economically, components that have a very high degree of complexity.

Properties of the Bergomat:

- Rotary transfer machine with up to 93 CNC axes

- Six-sided machining

- Flexible loading options

- Up to max. Ø 50 mm from the bar

- Up to max. 100 mm edge length / chuck parts

- Up to max. 180 mm workpiece lengths

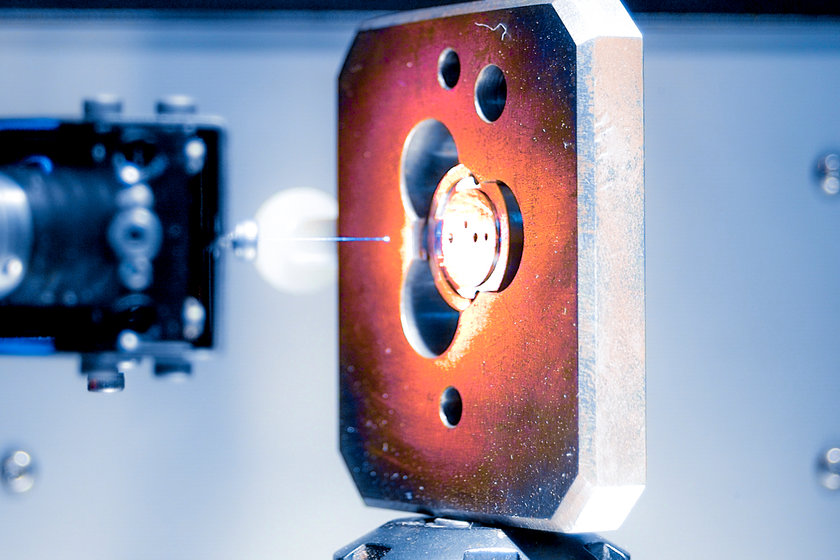

Tool development

Established in 2002, and owned by the Berger Group since 2013, ProProTec Präzisionswerkzeuge GmbH & Co. KG is a company that offers a broad spectrum of specialized tools and dies. ProProTec offers 3D-CAD systems, high-precision tool grinding and tool eroding machines, and measuring technology. Tool development has become a core competency for Berger, and our customers have benefited greatly from this area of expertise.

You can find further details here: www.proprotec.de

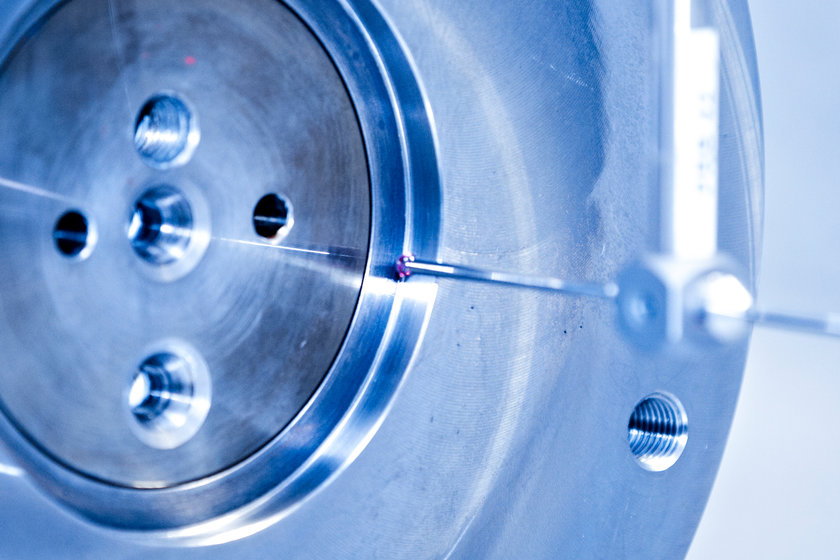

Heat treatment

With our in-house hardening facilities at our Memmingen and Poland locations, Berger has enjoyed worldwide recognition for our hardening technology. We also enjoy many partnerships with leading companies, for example in the automotive and machining industries, that rely on Berger for their custom heat treatment needs. On top of heat treating parts that we have manufactured in-house, we are also happy to serve as a subcontractor for customers who require our hardening facilities.

Here you can find out more about the hardening techniques used at Berger.

Assembly

Quality assurance

We stand for quality

Our philosophy is to guarantee a maximum degree of quality in all corporate sectors.

Our reliability is reflected in our long-lasting customer relationships. Our customers regard us as a valued partner for complex products because we assure efficiency in our ability to handle even the newest technical requirement of our customers. We comply with industry standards through continuous certification processes. Berger is proud to be certified according to the IATF 16949. For over 20 years, our facilities have held these industry standards, and are proud to share these same standards to all our customers worldwide.

Berger is currently embarking on implementing all the crucial elements of Industry 4.0, ensuring that the quality expectations of our customers will be assured in the years to come.

Solutions that exactly match your needs

Contact us